Quote:

Originally Posted by Fritzcat

A nice looking rifle, I would like some info on suppresor.

|

it's an M baffle design. Not my design, but one I copied from the Silencer Talk forum. All the credit for this design goes to Sub-Sonic on the silencertalk forums, it was his design and from videos he has posted it works extremely well

the entire cost of the silencer was about $250 ($200 for the Tax stamp and about $50 for materials)

$10 for the Stainless Tube

http://www.onlinemetals.com/merchant...d=19&top_cat=0

$16 for the freeze plugs

http://www.clipsandfasteners.com/1_1...gs_p/a3965.htm

the other $24 was spent on shipping for the above items and on a few miscellaneous parts like the pipe fitting that was welded to the can and blind pinned to the barrel

I didn't have access to a CNC Lathe or CNC Mill so I had to use a simple to make design.

Here is a link to the design I copied. You will need to join the forum to view the entire post

http://www.silencertalk.com/forum/viewtopic.php?t=19231

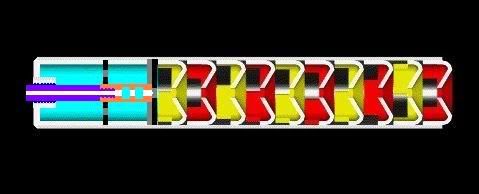

I used 1.625"x12" 304L stainless for the tube. The ID is 1.495". and I made the baffles out of 1.5" freeze plugs that were subsequently bent into M baffles.

Below are a few pictures (again not mine, but from the original post of the silencersmith form) showing the baffles and how to make them

Place a 3/8" ball bearing in the enter of the freeze plug and place the freeze plug on an appropriately sized socket

Tape it to the freeze Plug and place it into a vice

Clamp down on the vice

Dill your bore hole and grind out some of the freeze plug skirt to reduce weight

I overview of the design....except that mine is permanently attached with welded in place blind pins