Quote:

Originally Posted by 320pf

In an earlier post someone came up with a way to make 300-221 fireball brass using a small tube cutter to cut 223 brass near the shoulder. The next step involved running the brass into the sizing die and then trim to length.

Well I tried this method and it was way too slow. But it led to another method to form brass that is pretty quick.

First, with the .223 collet installed, trim .223 brass past the shoulder to a length of 1.365". I use a Foster trimmer with an attachment for a drill.

The brass at this point will look like a long version of a rimless 357 mag.

Run this brass into the sizer-deprimer die and you have a 300-221 fireball case.

I can make about 100 cases in little over an hour.

320pf |

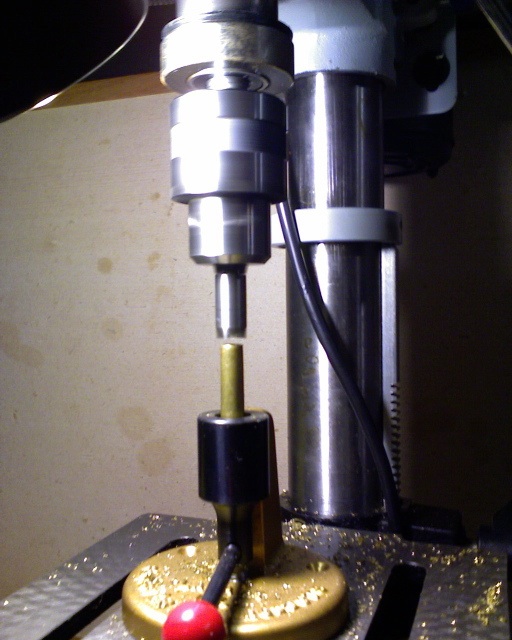

Since this post, I have updated the method. I now use a Forster power trimmer.

Here is the starting 5.56/223 brass mounted in the Forster power trimmer.

Here is the "trimmed" intermediate-step brass.

Run this brass into the sizer-deprimer die and you have a 300-221 fireball case.

I made these cases over a Saturday afternoon.

I hope that this helps those who are looking for ways to make 300-221 Fireball brass

320pf