|

|

10-31-2010, 08:39 AM

|

|

Member

|

|

Join Date: Feb 2009

Posts: 60

|

|

Quote:

Originally Posted by rsilvers

You are loading to too high a pressure. 18.5 grains of H110 with a Nosler 125 to that OAL is not reasonable.

|

Any suggested loads to try out for a supersonic with 125 Noslers and H110? I have other powders as well I could use.

|

10-31-2010, 10:20 AM

|

|

Member

|

|

Join Date: Feb 2009

Posts: 60

|

|

Quote:

Originally Posted by rsilvers

You are loading to too high a pressure. 18.5 grains of H110 with a Nosler 125 to that OAL is not reasonable.

|

Is it the OAL or the charge? I chose the load due to reading this link from this site:

http://quarterbore.com/300whisper/supersonic.html

It recommended 22 grains of H110, so I loaded down more than 10% thinking it was safe - should I try something like 17 grains?

|

10-31-2010, 10:36 AM

|

|

Super Moderator

|

|

Join Date: Mar 2010

Posts: 281

|

|

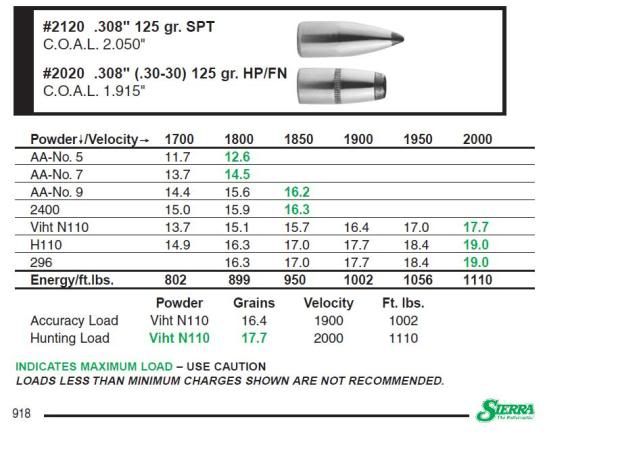

Here is what Sierra shows in the book

|

10-31-2010, 11:03 AM

|

|

Senior Member

|

|

Join Date: Jun 2009

Posts: 122

|

|

Quote:

Originally Posted by grey2112

Case neck OD on loaded round = .330

Neck measures OD on a spent case fired in 8" = .333

Neck measures OD on a spent case fired in 16" = .336-.339

Case length on loaded round (both super and sub) = 1.363-1.366

Case length on fired round from both = from 1.355-1.385

|

Based on those numbers it doesn't sound like the neck is too tight. It wouldn't hurt to check the rest of the case dimentions in the same fashion because overpressure ammo wouldn't be causing the loaded rounds to stick in the chamber before they are fired.

Speaking of that, in your first post you said that unfired rounds weren't sticking and later you said they were. Could you clarify?

As for the load, 22.0 grains of H110 sounds awful hot. In the link it also shows an MV of over 2400fps with the 125gr Nosler, which is about 200fps more than I would expect from a 16" 300 Whisper. It was from a bolt action so perhaps JD was just pushing it really hard, but I wouldn't be comfortable with 22.0 grains. With the 18.5gr load your problem may be your loaded length. The 125gr Nosler is longer than most 125gr .308 bullets and if you load it too deep it is eating up case capacity and can lead to higher pressures.

|

10-31-2010, 11:33 AM

|

|

Senior Member

|

|

Join Date: Mar 2010

Posts: 482

|

|

Quote:

Originally Posted by grey2112

Is it the OAL or the charge? I chose the load due to reading this link from this site:

http://quarterbore.com/300whisper/supersonic.html

It recommended 22 grains of H110, so I loaded down more than 10% thinking it was safe - should I try something like 17 grains? |

That chart is missing OAL data - which is pretty surprising. When it is unspecified, you have to assume it is the max. You are way less than max OAL. Even so - even at max, that load seems too hot and I would never try more than 21.5 at max OAL. That is a max max load probably with a slow lot of powder and a generous chamber.

If you bring it out to 2.100 OAL then you will likely be fine with 18.5.

You can see Sierra lists 19.0 as a max load for a flat base bullet. The Nosler is a boat-tail and so uses up more case capacity for any given OAL. So I still say 18.5 if you extend your OAL.

__________________

R&D for AAC

Last edited by rsilvers; 10-31-2010 at 11:36 AM.

|

10-31-2010, 12:46 PM

|

|

Senior Member

|

|

Join Date: Oct 2009

Location: West Virginia

Posts: 123

|

|

|

As H110 is a relatively slow powder for the Whisper seems likely to have a long pressure curve and you described your primers as "flat," I would first suspect your loads are too hot.

Is wise to remember that even cannister grade (commercial) powders vary enough that max loads should be worked up for a new lot of powder.

Ever check the velocity of your load?

|

10-31-2010, 01:42 PM

|

|

Member

|

|

Join Date: Feb 2009

Posts: 60

|

|

|

Thanks for the data, guys - I really do appreciate it. I'd like to get this resolved as I've had thoughts of chucking the barrel and getting a 7.62x39 to replace it, or some other flavor and I'd rather not spend the $$ :)

I'll pull the bullets, resize, go with 17 gr. of H110, and extend the OAL and see what happens.

Oh, and I'll also clean the hell out of the chamber and make sure there are no burrs.

|

10-31-2010, 01:44 PM

|

|

Member

|

|

Join Date: Feb 2009

Posts: 60

|

|

Quote:

Originally Posted by alorton

Based on those numbers it doesn't sound like the neck is too tight. It wouldn't hurt to check the rest of the case dimentions in the same fashion because overpressure ammo wouldn't be causing the loaded rounds to stick in the chamber before they are fired.

Speaking of that, in your first post you said that unfired rounds weren't sticking and later you said they were. Could you clarify?

.

|

Originally they were, but then they started sticking. When I was at the range my first 5 rounds at 25 yards (to sight in a new scope) worked great (loaded, ejected, loaded, etc.) in the 16" with the supersonic rounds. But when I moved to 50 yards and started up again that is when they started sticking.

|

10-31-2010, 03:27 PM

|

|

Senior Member

|

|

Join Date: Apr 2009

Posts: 178

|

|

|

I'd say your neck in the chamber is carbon fouled, and making extraction difficult. Are you using a can with this rifle? Are the necks of your ejected brass sooted up? I have ran into this problem before in a bolt gun where the loads were not building sufficient pressure to seal the chamber, and the gas was getting into the neck area. Had to beat the bolt open to extract the brass. Took a bronze brush to the neck of the chamber, got the carbon out, and the problem went away. Have you brushed out your chamber? A rotating 9mm or 35 CAL bore brush will work with your .335"-ish neck OD. If you have a short pistol cleaning rod and a cordless drill, that will work the easiest. Try that and get back to us.

Kevin

__________________

Can you hear that? It's our founding fathers turning over in their graves...

|

10-31-2010, 04:11 PM

|

|

Member

|

|

Join Date: Feb 2009

Posts: 60

|

|

|

I feel rather weird asking this, but as my Dad once said - there are no stupid questions, only stupid people.

I have a Redding die set, 2 dies. One is a seating die, the other I assume is the full-length sizing/depriming die.

Could someone give me a down and dirty step-by-step on how to create a round? It has been a while and maybe I'm missing something - like I've got the dies not set up right, etc.

The way I recall was take clean brass, lube (not too much), set up resizing die so that it touches the shellholder and then back out enough so that it engages when the lever is pulled down but not where it requires a herculean effort. Then prime, put powder in, seat bullet.

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -4. The time now is 08:42 AM.

|