Quote:

|

Originally Posted by abyssdncr

Still need to drill the gas port... The original hole was 0.125".

With the intent of adding the adjustable valve to the gas tube, is there any reason not to just drill out to 0.125" and turn the gas down as necessary?

[8D]

|

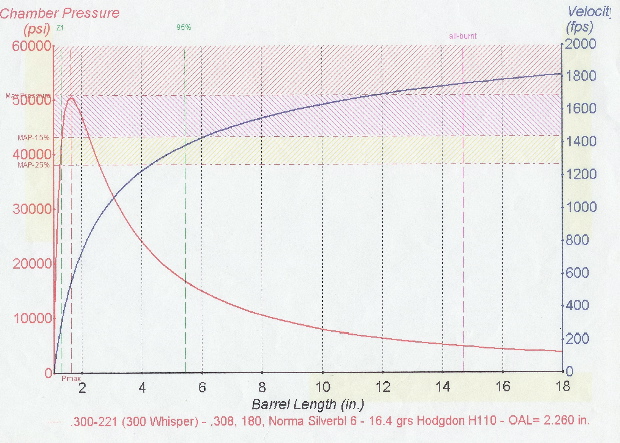

For a pistol length gas system I would start with a gas port of 0.073". The pressure at the gas port position is much higher than the carbine position. This photo is a plot of gas pressure for a 180 gr super sonic load. The pistol gas port position is located about 4.5" from the breech and the carbine position is about 8" from the breech.

For a sub-sonic load the maximum pressure runs about 25000-40000 psi. So to get an idea of the pressure you can scale the pressure curve in the about diagram. You will probably end up with a gas port of around 0.080 to 0.085. If you get the gas port diameter right you will be able to shoot both sub-sonic and super-sonic loads without an adjustable gas block or tube. This will make your life much easier.

Just make sure you set your depth so you do not drill into the other side of the bore (I am not trying to insult your intelligence just being layer like with the disclaimer

)

/300%20Whisper%20page%2076.pdf)

)

Quote:

|

Originally Posted by abyssdncr

Also, on drilling the hole, what's the best way to keep from getting burrs inside the bore? Tap a bullet down the bore to "catch" the drill bit as it goes through?

[8D]

|

Do not worry about any burrs that you will get drilling the gas port. After you shoot about 10-20 rounds through the barrel the burrs will be gone.... After about 100 round.... burrs??? what burrs?

Good Luck and have some fun

320pf